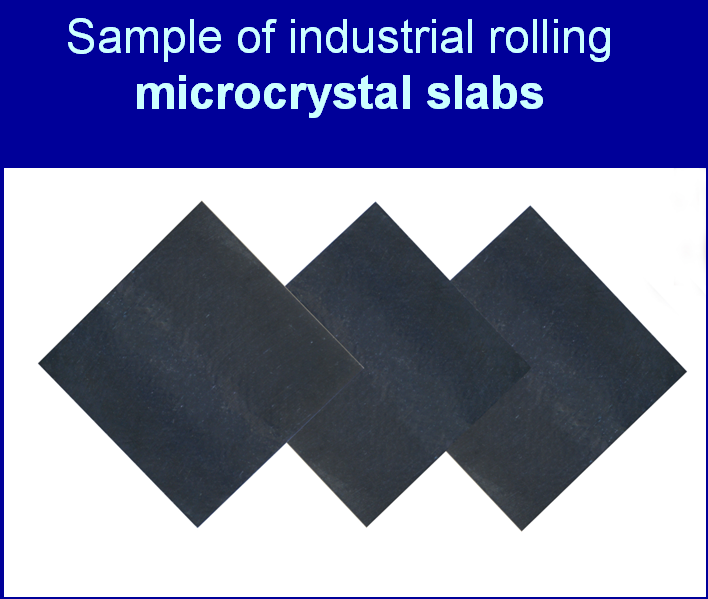

industrial rolling microcrystal slabs

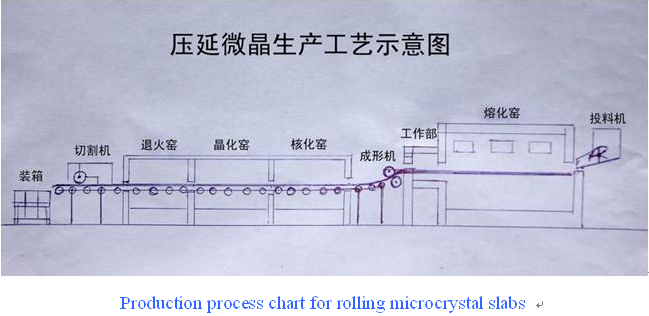

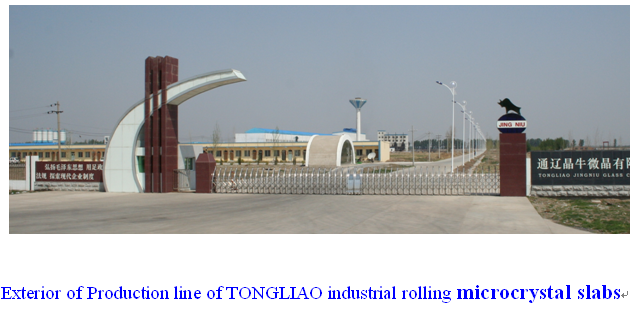

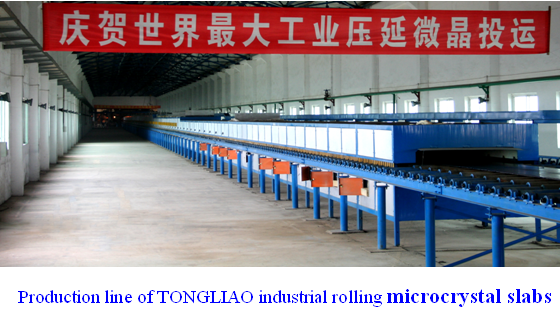

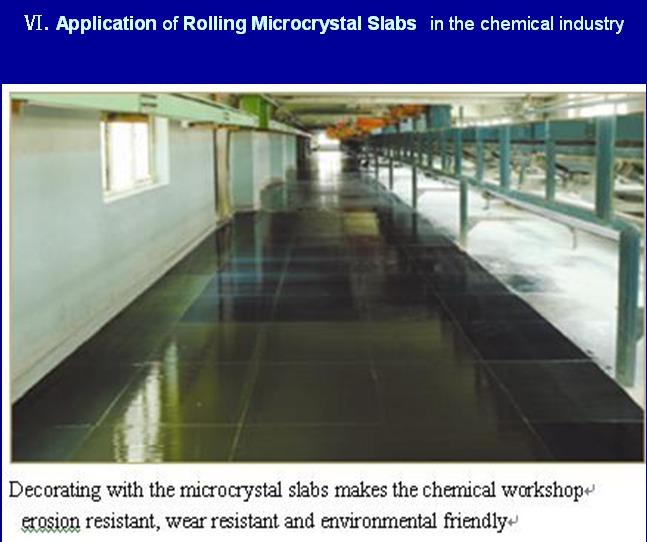

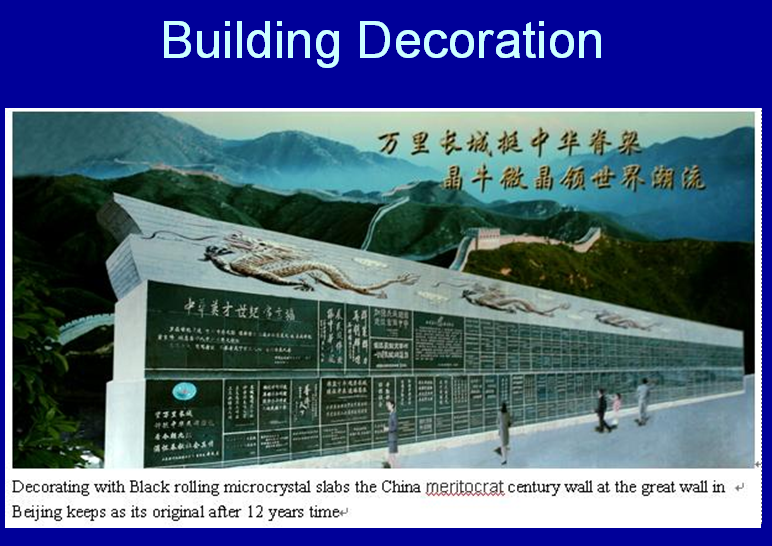

Industrial microcrystal slabs was developed by China Jingniu Glass Ceramics Group Co. Ltd. which spent 20 years including 10 years’ product developing and 10 years’ market developing. The product is a high tech product with R & D cost of RMB1.2 billion which fill the national gap. The Group established the first national standard of Industrial microcrystal slabs in China. The product is made from various mineral waste residues, through the process of melting, rolling and forming, crystallizing, annealing. It is a hi-tech industrial protective material with the properties of high strength, high wear resistant, erosion resistance . The product can massively substitute cast stone, stainless steel, cast iron, UPE high density board, acid-proof brick, granite, marble, etc. The products can be widely applied to the industries of coal, steel, metallurgy, power, chemistry, etc. such as the bunkers, hopper, sluice scraper device and other locations of surface process .In the meantime, as a building decoration material, the product is a environmental friendly building material with its properties of bright and clean, elegant appearance, without color aberration, no air slaking, no radio contamination.

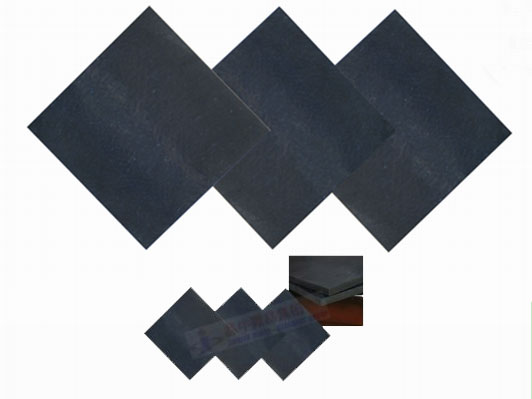

The character of Rolling microcrystal slabs and its varieties, color, specification

- The major varieties of rolling glass ceramics: industrial original slabs, polished industrial slabs, decoration original slabs, polished decoration slabs

- major color: pearl black, ivory white, Agate Red , natural grey

- plate size: thickness: 6mm---20mm

width: 800 mm

- character: wear resistant, erosion resistance, impact resistance; bigger specification,plate is thinner,the surface is even and straight;no radiation,no pollution,zero water absorption rate, high brightness;light in weight,convenient for cutting operation.

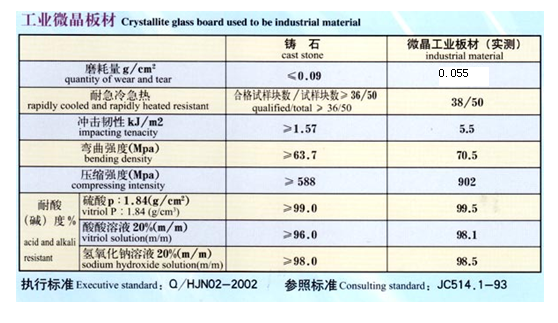

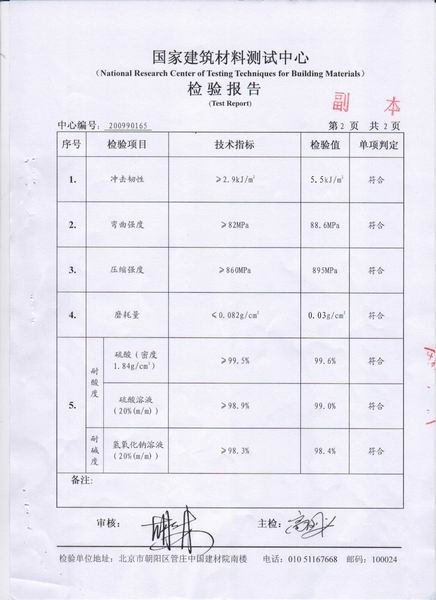

Rolling microcrystal slabs get excellent wear resistant, its wear-resisting extent reaches 0.055g/cm2, which is 2-3 times that of the cast stone (0.09g/cm2),7-8 times that of manganese steel, 15-20 times that of cast iron.

2. Erosion resistance

The erosion resistance of Rolling microcrystal slabsis superior to acid-proof bricks, marble, granite, and common cast stone. It has both acid & alkali resistance, especially it can also be used in the surrounding of the acid & alkali shift.

3. Impact resistance

The impact resistance of Rolling microcrystal slabs can reach 3.08KJ/M2, it is 2 times that of common stone, and can meet the need of major material conveying locations.

4. Low friction coefficient

The friction coefficient is only 0.05, its surface becomes more smooth with more usage.No hanging ocurrs, which avoids blocking the bunker with more material hanging on the surface.

5. Thin & light

The range of the thickness of Rolling microcrystal slabs is 8 -20mm. Most cases, the 14mm can simply meet the practical needs. Its specific gravity is only 2.72g/cm3, which is one third of steel, It can increase the inner cubage of the bunker, and decrease the weight of the equipment and the bunker itself.

6. Site cutting

Rolling microcrystal slabs can be cut on site with portable cutting saw,which is convenient for construction installation.

7. Environmental friendly and no pollution.

History of the development of industrial rolling glass ceramics plate in China

On Aug.15,1994,Official start of the construction of Xingtai Production line;

In 1995,Ignition put into production;

In May 1999,Scale production & meet the standard;

On Oct.14,1999,passed The Expert Appraisement at Beijing diaoyutai state guesthouse

obtaining 4 items of national patent;

In Oct.2002,obtaining patent gold award;

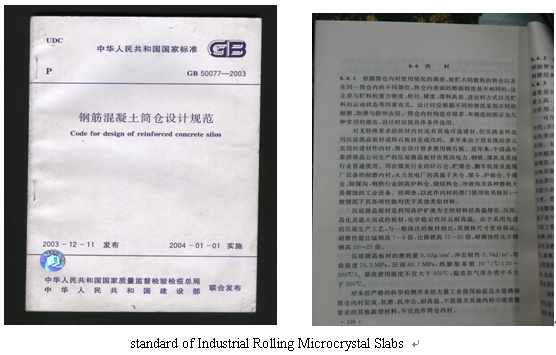

In 2004,the product was listed in “The People's Republic of Reinforced Concrete Silos Design Specification”(GB50077-2003) , and thereby special explanation is made on rolling microcrystal slabs, saying Jingniu Group is the drafting unit;

In Jan.2011, examine and approve on the standard of China “Industrial microcrystal slabs” which is drafted by Jingniu Group;

In Dec.2011, “Industrial microcrystal slabs” was issued in China.

On Aug.15,1994,Official start of the construction of Xingtai Production line;

In 1995,Ignition put into production;

In May 1999,Scale production & meet the standard;

On Oct.14,1999,passed The Expert Appraisement at Beijing diaoyutai state guesthouse

obtaining 4 items of national patent;

In Oct.2002,obtaining patent gold award;

In 2004,the product was listed in “The People's Republic of Reinforced Concrete Silos Design Specification”(GB50077-2003) , and thereby special explanation is made on rolling microcrystal slabs, saying Jingniu Group is the drafting unit;

In Jan.2011, examine and approve on the standard of China “Industrial microcrystal slabs” which is drafted by Jingniu Group;

In Dec.2011, “Industrial microcrystal slabs” was issued in China.

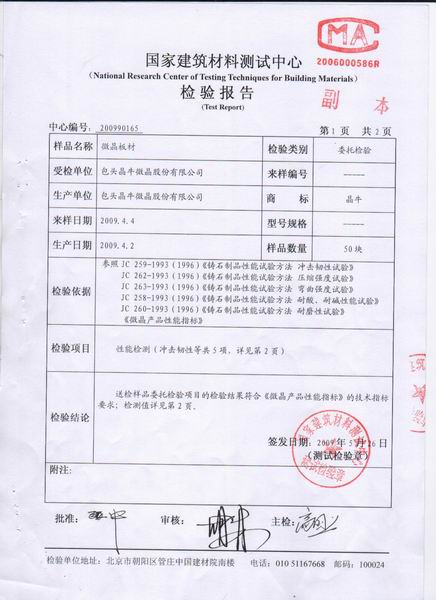

Honor & Patent Certificate

•The standard making unit of Industrial microcrystal slabs in China,the major hi-tech enterprise & executive unit of the State Torch Plan, innovation award of cooperation between production,institute and research, 14 patent of items,such as microcrystal glass furnace bath,forming machine,annealing track pit,obtaining the best item title of China 15 year’s Patent exhibition of achievement.

PRACTICAL CASE:

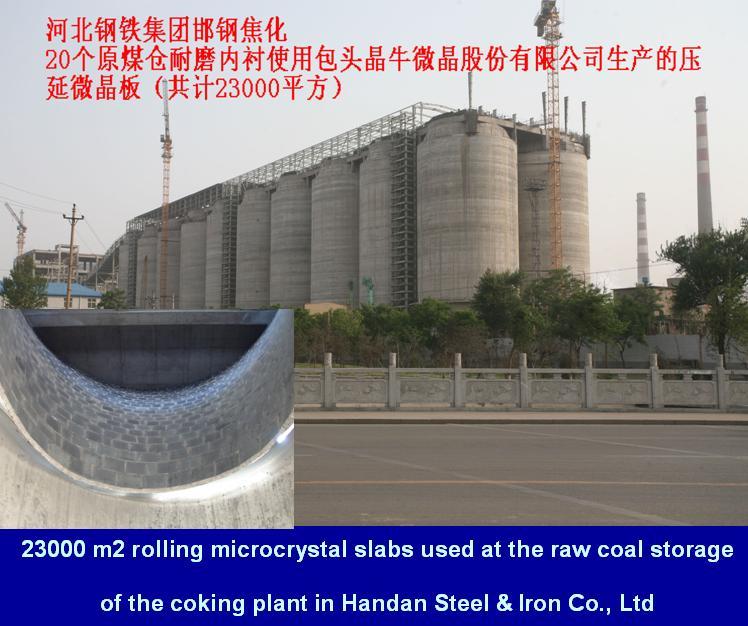

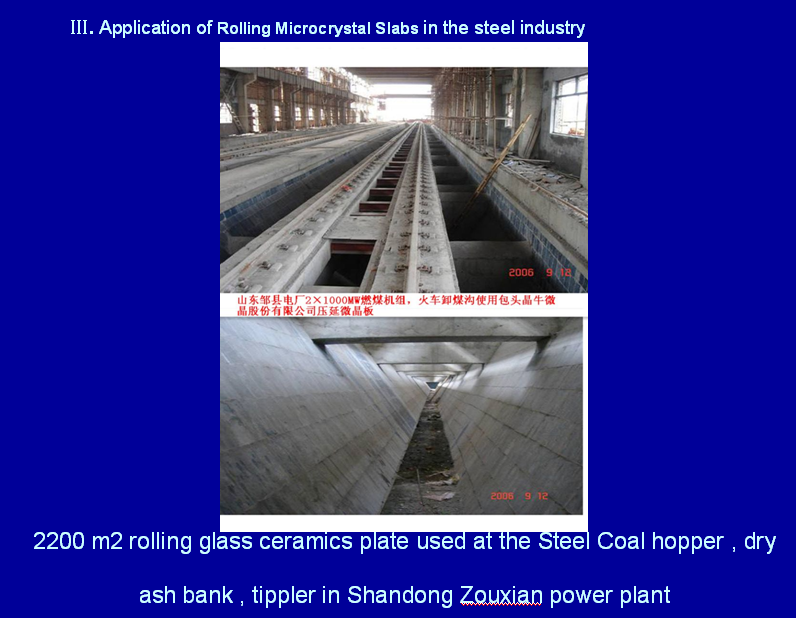

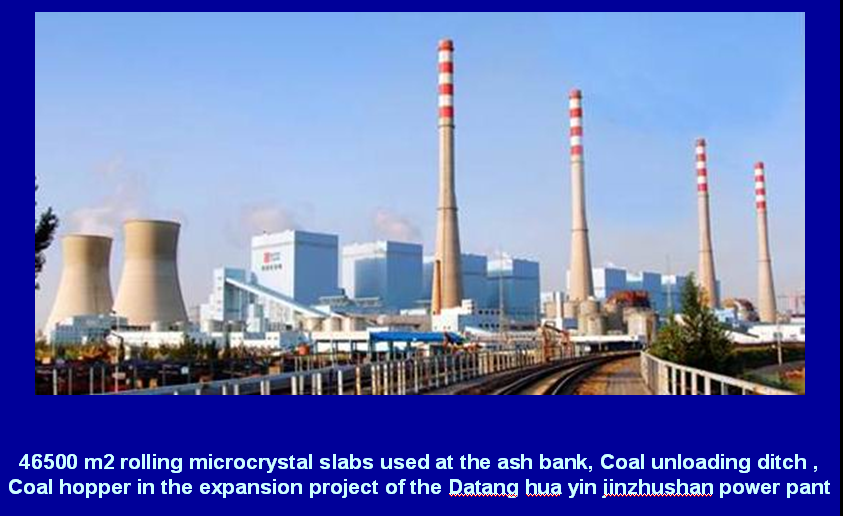

Since the inception of Rolling microcrystal slabs, 500 well-known enterprises from the industries of steel,power, coal,coking,chemical etc., such as, India Electrosteel Integrated Ltd.(EIL), Tangsteel Group, Laisteel Group, Handansteel Group, Shasteel Group, Shougang Group, and Wuhan Iron And Steel Company Limited,Malysia Mukah power plant,2th phase of th project of Jiangsu Leogane Power plant,Expansion project of Datang Huanyin Jinzhushan Power Plant, Dangtang tuoketuo power plant,2nd Adolescence project of Shangdong Weifang Power Plant;Shangdong Jining International Coking,Shangxi jiexiu Coal Washery,Shanghai Coal Steel Coking, etc. firstly use microcrystal slabs getting the aim of energy saving, consumption reduction and efficiency increase .

steel industry

power industry

coal industry

building decoration

More than 60 designing institutes & cooperation units:

Power designing institute: NCPE, reconnaissance & Design Institute of Power Industry

in Guangdong(Guangxi ,Fujian,Hunan,Jilin),North East (North west, Anhui, Inner Mongolia) power designing institute,

SHANDONG ELECTRIC POWER ENGINEERING CONSULTING INSTITUTE(SDEPCI),etc.

Metallurgical steel design institute: Shandong provincial Metallurgical design institute Co., Ltd. Beijing steel design institute, China

metallurgical Coke Resistant Engineering Co.,Ltd.

Designing Institute of Handan Steel & Iron Co.Ltd.

China metallurgical (Jingcheng, heatresisting,North,South) Engineering Co., Ltd. etc.

Coal Designing Institute: Shanxi Coal Designing Institute, Northwest Coal Designing Institute, Beijing Coal Designing Institute, Saiding

Engineering Co.,Ltd.Tangshan Coal Designing Institute, etc.

Chemical engineering Designing Institute: Dalian Dahua Designing Institute,Hua Liu

Institute,etc.

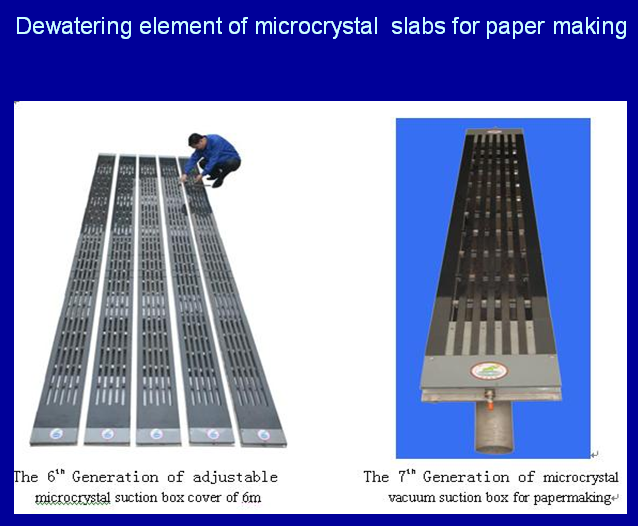

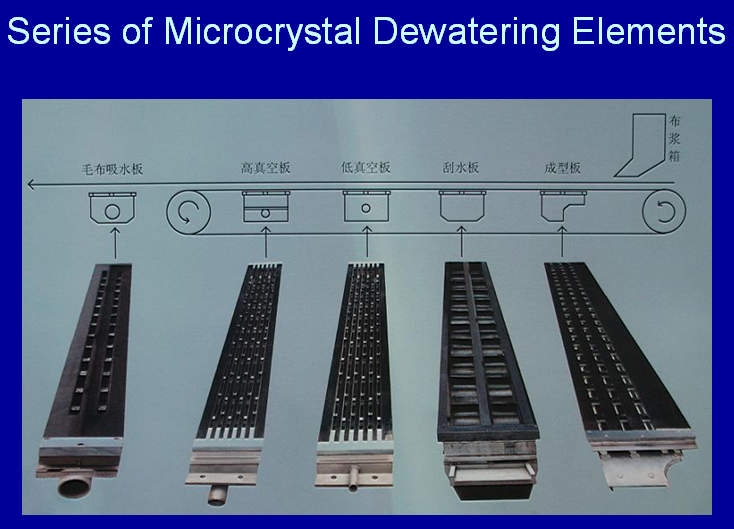

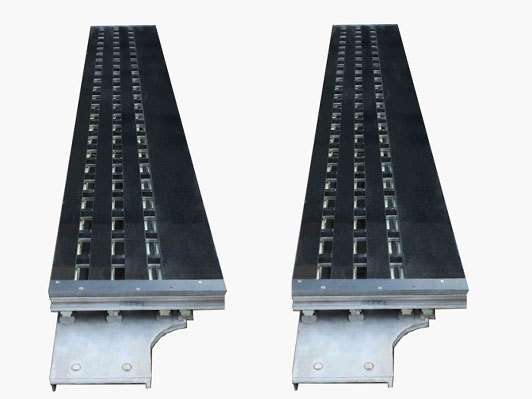

the second revolution of Paper Industry:

Supporting with the high strength erosion resistant aluminium alloy frame of excellent quality, by high-precision milling the surface of the base material into mirror-surface grade with CNC equipment, the whole dewatering equipment of microcrystal is processed with the China unique high tech rolling microcrystal plate as the base material which is solely developed by Jingniu Glass Ceramics Group Co., Ltd. The product has the property of whole body board & even and smooth surface without any connection gap on the top, wear resistant with low friction coefficient, fine and smooth material quality, same quality of both its interior and exterior. The product is used for dewatering in the fourdrinier section, obtaining the aim of saving mesh & power and improving the quality & the productivity. Which solve the difficult problem of “While Using UPE, the top board is not wear resistant, while using ceramic, the mesh is not wear resistant”. The product has been used by the 300 domestic paper mills, which is satisfying with a good result of creating RMB10 billion annually. The second revolution of paper industry thereby is called regarding the renovation of the fourdrinier section.

Microcrystal dewatering equipment for paper making is suitable for various pulps of bamboo pulp,reed pulp,wood pulp,straw pulp and sugarcane pulp

•Specialty paper: Shanghai Mint

Tianjin Mint

Jiamusi Paper Co., Ltd. Heilongjiang

Sun Paper Co., Ltd. Shandong Province

•Paper Mills of bamboo pulp: Yongfeng Paper Co., Ltd. Sichuan Province

Fuhua Paper Co., Ltd., Leshan, Sichuan Province

Yibin Paper Co., Ltd., Sichuan Province

•Paper Mills of reed pulp: Meili Paper Co., Ltd., MCC

Tianhong Paper Co., Ltd., Xinjiang

Bohu Reed Co., Ltd. Xinjiang

•Paper Mills of wood pulp: Sida Paper Co., Ltd., Heilongjiang

Huajin Paper Co., Ltd., Jilin province

Changle Shiji Sunshine Paper Co., Ltd., Shandong Province

•Paper Mills of straw pulp: Changxing Paper Factory, Shaoyang, Hunan Province

Fengli Paper Co., Ltd., Yueyang, Hunan Province

Binggong Paper Co., Ltd., Jingzhou, Hubei Province

•Paper Mills of bagasse pulp: Forestry Lipu Paper Co., Ltd. Guangxi Province

Sugarcane Chemical (Group) Co., Ltd. Jiangmen, Guangdong Province

冀公网安备 13050002000752号

冀公网安备 13050002000752号